PCB Etching Workshop

Preparing for the Workshop

- Make sure you've run through the workshop before the day of the workshop. There are many aspects

- This workshop is maximum of 8 people. If you only have 1 printer and/or 1 laminator consider reducing class to a size of 6.

Topics

- Overview of the process including alternatives

- Copper clad variations and acid options (including disposal)

- Transfer sheet and transfer method options

- Hands on making!

Steps

- Print design on paper and mock the board layout to make sure the print is scaled correctly and the mirroring is correct.

- Cut transfer paper about an inch oversized and tape it to the original print. Print again on the glossy side of the paper.

- Cut copper clad to approximate size - about an inch over sized again.

- Using painters tape, tape 1 or 2 edges of the transfer to the copper.

- Run through the laminator 5 - 10 times (until you're tired of doing it)

- Soak copper and transfer in water for a couple of minutes, then peel off the transfer.

- Use 2 sandwich bags and etch the board with ferric chloride

- Drill the holes using drill press or dremel press.

- Solder, Test, and Done!

PCB Equipment Needed for Space

Here's a link to the equipment at hackrva for PCB etch: PCB_Making_Equipment

Here's a link to a supply list for this workshop: https://docs.google.com/spreadsheets/d/13CzrknA-gje8imDsIwGcc6N7ohlUdvaHhMr8B-QhfR0/edit#gid=0

Example Projects for Teaching

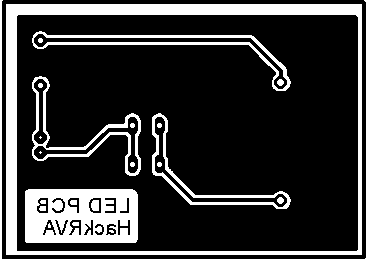

PCB Workshop Blinky 1

This is a simple LED board at about 2"x3" inches.

Parts List

- (1) Button

- (1) Battery Holder

- (1) Resistor

- (1) LED