PCB Etching Workshop: Difference between revisions

Jump to navigation

Jump to search

Aaronn0130 (talk | contribs) added equipment and supplies section |

Aaronn0130 (talk | contribs) |

||

| Line 4: | Line 4: | ||

* Make sure you've run through the workshop before the day of the workshop. There are many aspects | * Make sure you've run through the workshop before the day of the workshop. There are many aspects | ||

* This workshop is maximum of 8 people. If you only have 1 printer and/or 1 laminator consider reducing class to a size of 6. | * This workshop is maximum of 8 people. If you only have 1 printer and/or 1 laminator consider reducing class to a size of 6. | ||

==== Topics ==== | ==== Topics ==== | ||

| Line 10: | Line 9: | ||

# Copper clad variations and acid options (including disposal) | # Copper clad variations and acid options (including disposal) | ||

# Transfer sheet and transfer method options | # Transfer sheet and transfer method options | ||

# Hands on making! | # Hands on making! | ||

=== Steps === | === Steps === | ||

Revision as of 22:31, 6 March 2016

Preparing for the Workshop

- Make sure you've run through the workshop before the day of the workshop. There are many aspects

- This workshop is maximum of 8 people. If you only have 1 printer and/or 1 laminator consider reducing class to a size of 6.

Topics

- Overview of the process including alternatives

- Copper clad variations and acid options (including disposal)

- Transfer sheet and transfer method options

- Hands on making!

Steps

- Print design on paper and mock the board layout to make sure the print is scaled correctly and the mirroring is correct.

- Cut transfer paper about an inch oversized and tape it to the original print. Print again on the glossy side of the paper.

- Cut copper clad to approximate size - about an inch over sized again.

- Using painters tape, tape 1 or 2 edges of the transfer to the copper.

- Run through the laminator 5 - 10 times (until you're tired of doing it)

- Soak copper and transfer in water for a couple of minutes, then peel off the transfer.

- Use 2 sandwich bags and etch the board with ferric chloride

- Drill the holes using drill press or dremel press. (Find the right bits and make sure it works with dremel and drill press)

- Solder, Test, and Done!

Equipment & Supplies Needed for the Workshop

Maker sure you have the following:

- A working laser printer with good toner for printing image onto transfer paper.

- A computer for running the laser printer.

- PCB design artwork ready to be printed (and has been tested).

- Plenty of blue painters tape for securing paper to boards and paper to paper.

- Sufficient amount of toner transfer paper for class. Have extra for mistakes.

- Working laminator and clothes iron for applying heat during transfer process.

- A way to cut copper to correct size (shear(s) or table saw can work, have it ready in advance).

- Cleaning supplies to prepare copper; dish soap, sponge, paper towels, steel wool, fine-grit sandpaper (take your pick).

- Containers for soaking boards after toner transfer is complete (small tupperwares work well for this).

- Ferric chloride acid for etching boards.

- Nitrile gloves for handling acid.

- Sandwich bags for acid and copper (2 for each etch - double bag).

- Container for acid desposal or funnell for putting acid back in original container (depending on depletion).

- Correct size drill bits for hole drilling of PCB and fits available drill press.

- Marker or other item for fixing broken traces.

Here's a link to the equipment at hackrva for PCB etch: PCB_Making_Equipment

Here's a link to an order supply list for this workshop: https://docs.google.com/spreadsheets/d/13CzrknA-gje8imDsIwGcc6N7ohlUdvaHhMr8B-QhfR0/edit#gid=0

Other Tips:

- Make the traces and pads on the PCB artwork larger than needed to make etching easier.

Example Projects for Teaching

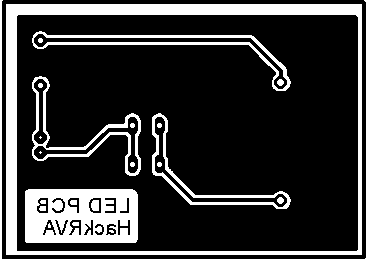

PCB Workshop Blinky 1

This is a simple LED board at about 2"x3" inches.

Parts List

- (1) Button

- (1) Battery Holder

- (1) Resistor

- (1) LED