Kramers tricopter step by step: Difference between revisions

Jump to navigation

Jump to search

mNo edit summary |

No edit summary |

||

| Line 2: | Line 2: | ||

'''essentially unintelligible, but I'm tired.''' | '''essentially unintelligible, but I'm tired.''' | ||

* Legs | |||

** sanded Legs | |||

** Assemble Motors | |||

*** attach the bottom braket | |||

*** get counter sink side correct | |||

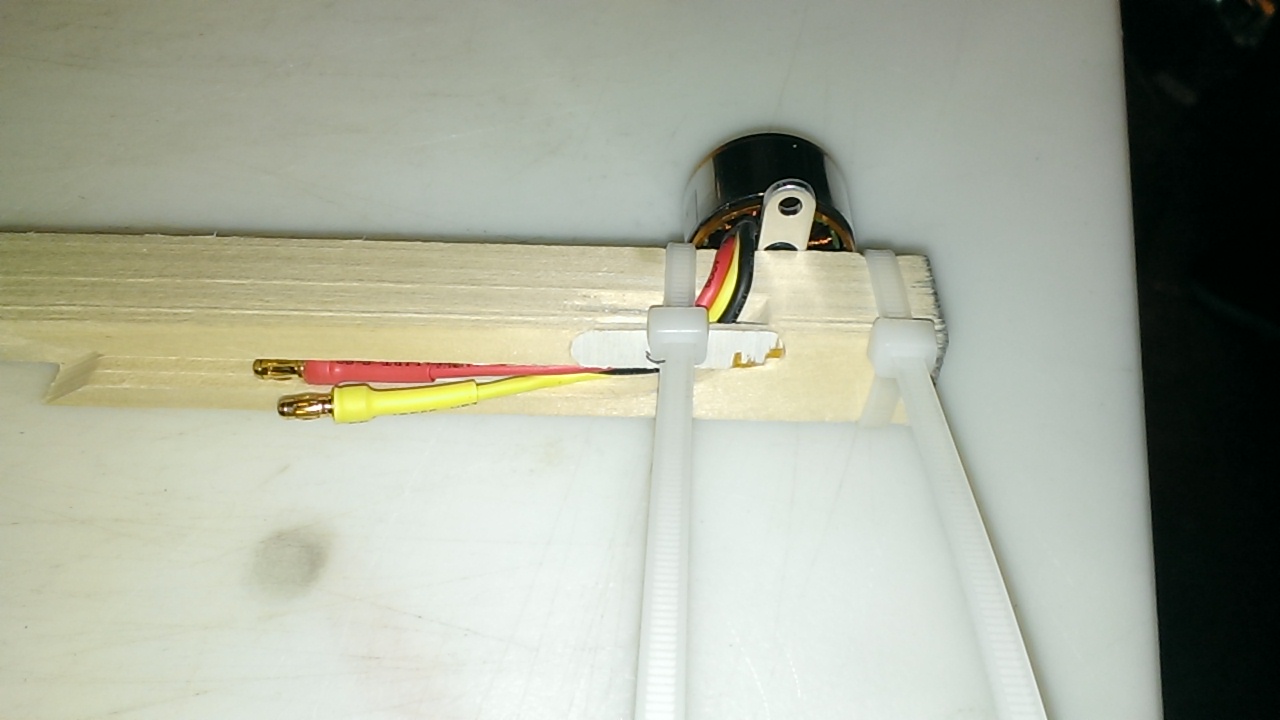

** Attach 2 non*servo motors to legs | |||

*** opposite side of screw holes | |||

*** align wires with opening | |||

*** use small cutout to enclose wires within leg slot | |||

**** could glue | |||

*** zip tie in place | |||

[[File:Kramers Tricopter Photo1.jpg|600px|thumb|center]] | |||

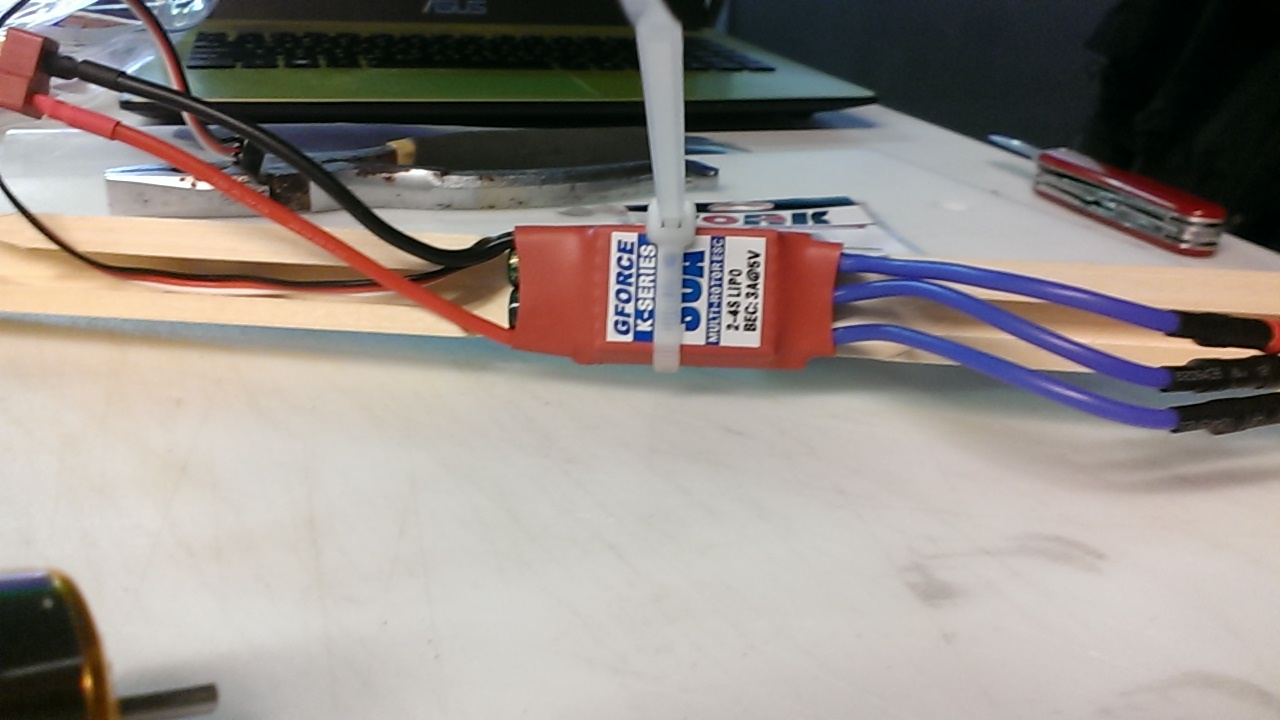

*** Zip tie and connect speed control | |||

*** will need to determine direction after build by running the motor and noting direction so don't make permanent | |||

[[File:Kramer's Tricoper Photo2.jpg|600px|thumb|center]] | |||

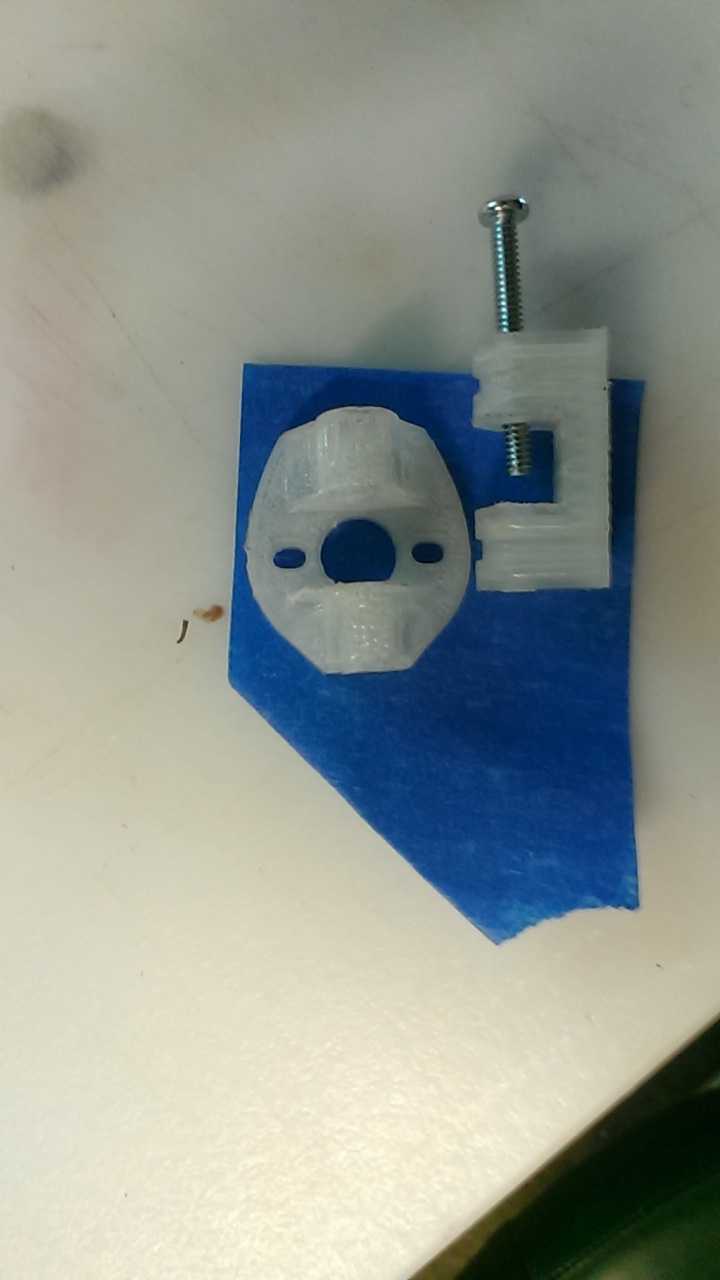

** drill and file 3D printed gimble mount | |||

*** use a screw and glue the end to make gimble pivot | |||

[[File:Kramer's Tricopter Photo3.jpg|600px|thumb|center]] | |||

*** use super glue | |||

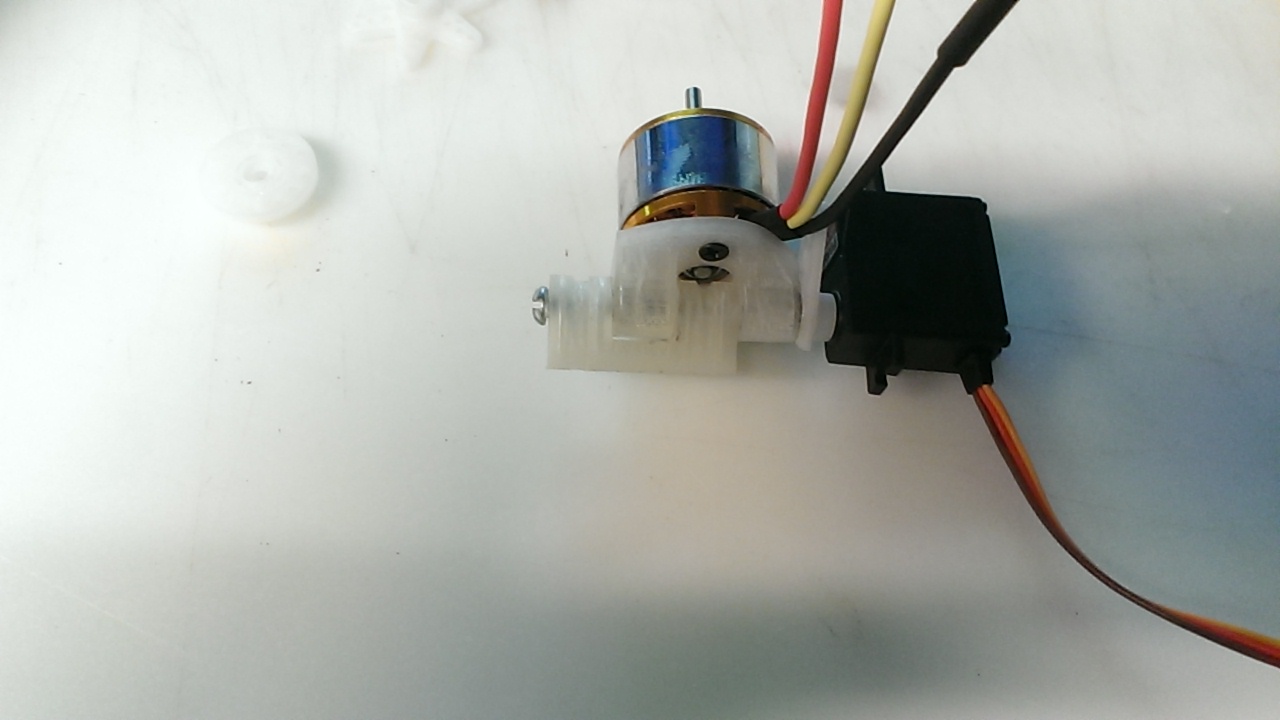

** screw motor on 3D printed mount | |||

*** may need to drill to fit | |||

*** align wires away from base end | |||

[[File:Kramers Tricopter Photo4.jpg|600px|thumb|center]] | |||

** Attach servo | |||

*** use drill to reverse counter sink screw hole to get a flush connection | |||

*** cut two edges of servo star to fit | |||

*** ensure full range of motion and attach star to servo | |||

*** superglue to gimble | |||

[[File:Kramers Tricopter Photo5.jpg|600px|thumb|center]] | |||

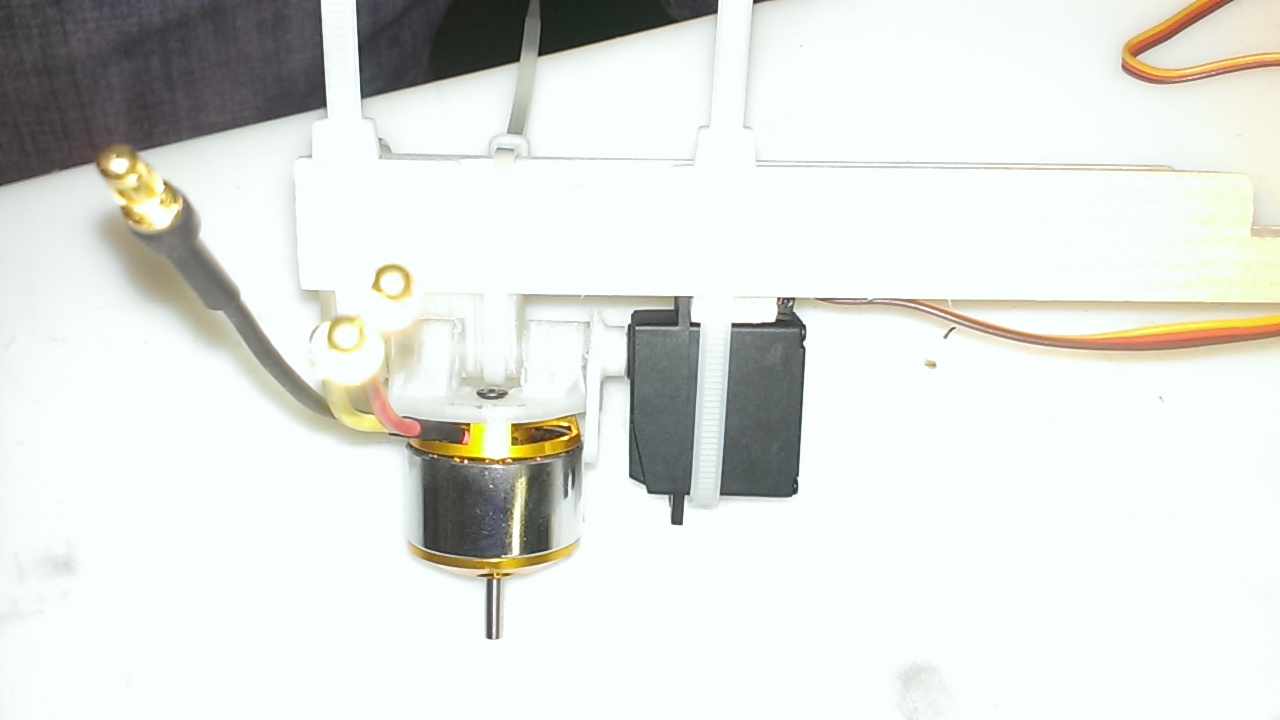

** Attach gimble and servo to leg | |||

*** Found out I made a mistake in how the wires were aligned with cutout on leg | |||

**** inscrewed and screwed | |||

*** use zip ties | |||

*** used super glue for spacer after zip tie | |||

[[File:Kramers Tricopter Photo6.jpg|600px|thumb|center]] | |||

** zip tie and connect speed controller | |||

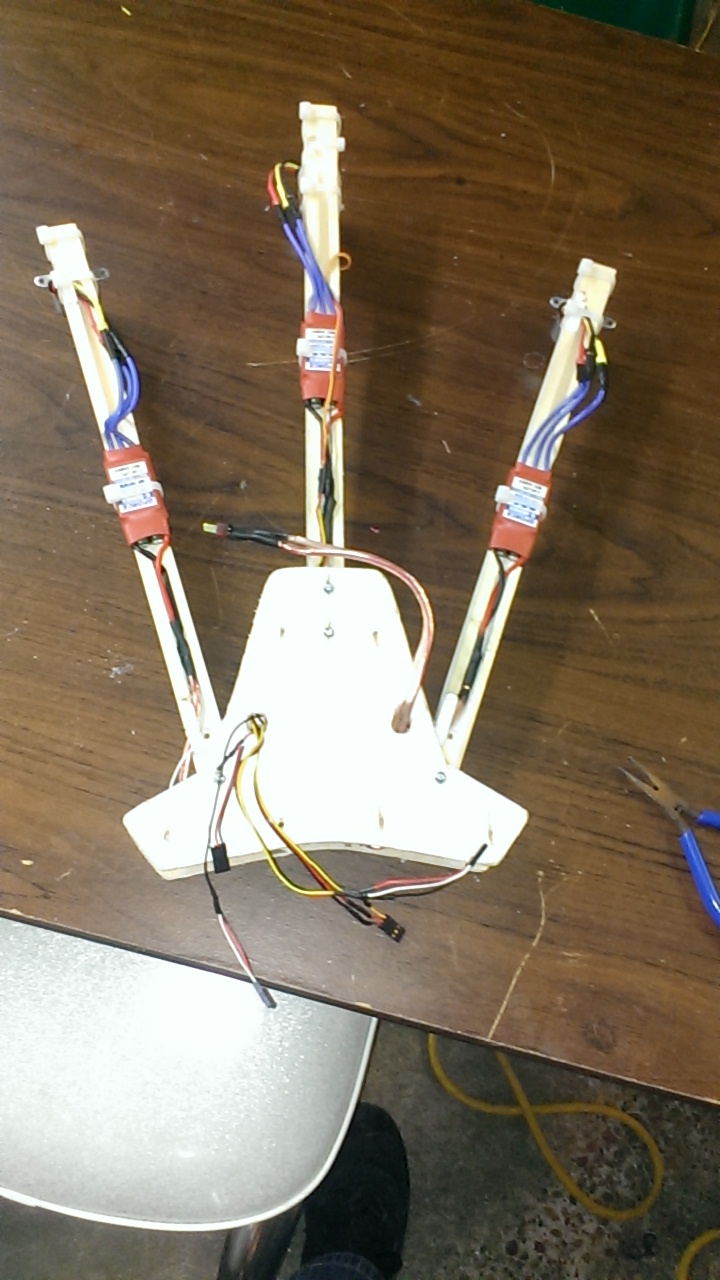

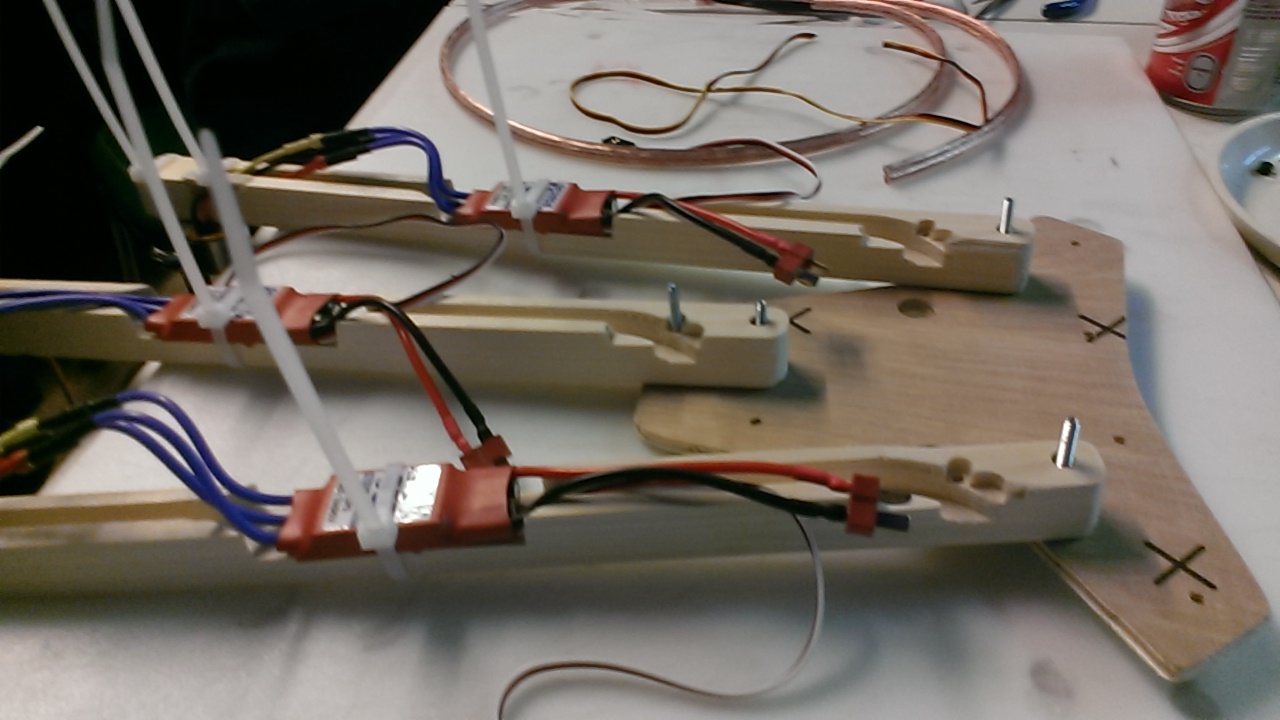

* Put the screws in a center piece and attach legs putting the gimbled leg in the center | |||

** use shorter 1 1/4 inch screw on inside for gimbled leg | |||

** attach so that the motors face down and the wires are accesable | |||

[[File:Kramers Tricopter Photo7.jpg|600px|thumb|center]] | |||

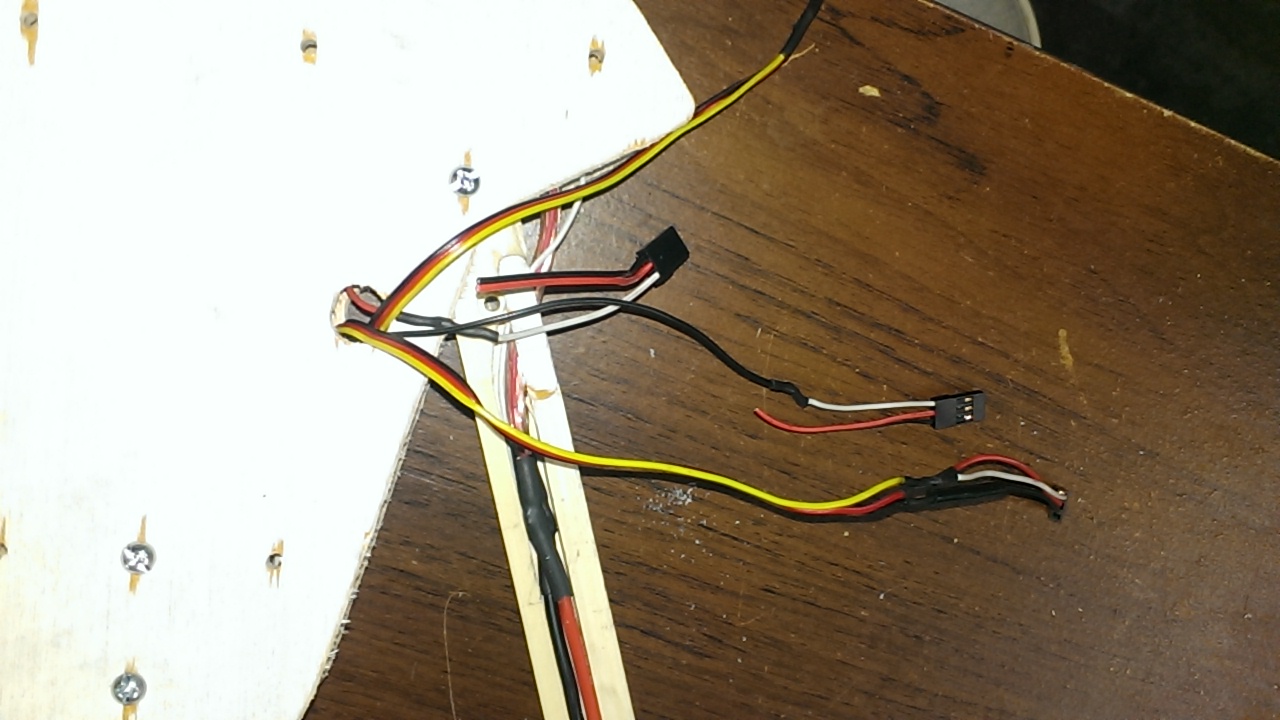

* connect wires together in middle using solder and speaker wire | |||

** pigtail all negative and positive from the speed controllers | |||

*** cut and strip black and red wires | |||

*** cut and strip speaker wire | |||

*** cut shrink wrap and solder wire red to red black to black | |||

[[File:Kramers Tricopter Photo8.jpg|600px|thumb|center]] | |||

*** lighter for shrink wrap | |||

*** combine all neg and wire to neg for final wire | |||

*** do the same for pos | |||

*** don't forget skrink wrap(large) | |||

** Extend all control wires | |||

** only the white wire from the two legs without the gimble | |||

** all three from the gimble | |||

** leave about 4 inches past the hole through the center section to the top | |||

** takes a while; don't forget the shrink wrap | |||

** attach the top plate | |||

** I messed up the side I soldered the large wires and had to flip the legs to make the bottom plate the top | |||

[[File:Kramer's Tricopter Photo11.jpg|600px|thumb|center]] | |||

[[File:Kramers Tricopter Photo10.jpg|600px|thumb|center]] | |||

Revision as of 11:44, 7 February 2015

Kramer's Documentation at end of day one 1/31/15 essentially unintelligible, but I'm tired.

- Legs

** sanded Legs

** Assemble Motors

*** attach the bottom braket

*** get counter sink side correct

** Attach 2 non*servo motors to legs

*** opposite side of screw holes

*** align wires with opening

*** use small cutout to enclose wires within leg slot

**** could glue

*** zip tie in place

*** Zip tie and connect speed control *** will need to determine direction after build by running the motor and noting direction so don't make permanent

** drill and file 3D printed gimble mount *** use a screw and glue the end to make gimble pivot

*** use super glue ** screw motor on 3D printed mount *** may need to drill to fit *** align wires away from base end

** Attach servo *** use drill to reverse counter sink screw hole to get a flush connection *** cut two edges of servo star to fit *** ensure full range of motion and attach star to servo *** superglue to gimble

** Attach gimble and servo to leg

*** Found out I made a mistake in how the wires were aligned with cutout on leg

**** inscrewed and screwed

*** use zip ties

*** used super glue for spacer after zip tie

** zip tie and connect speed controller

- Put the screws in a center piece and attach legs putting the gimbled leg in the center

** use shorter 1 1/4 inch screw on inside for gimbled leg ** attach so that the motors face down and the wires are accesable

- connect wires together in middle using solder and speaker wire

** pigtail all negative and positive from the speed controllers *** cut and strip black and red wires *** cut and strip speaker wire *** cut shrink wrap and solder wire red to red black to black

*** lighter for shrink wrap *** combine all neg and wire to neg for final wire *** do the same for pos *** don't forget skrink wrap(large) ** Extend all control wires ** only the white wire from the two legs without the gimble ** all three from the gimble ** leave about 4 inches past the hole through the center section to the top ** takes a while; don't forget the shrink wrap ** attach the top plate ** I messed up the side I soldered the large wires and had to flip the legs to make the bottom plate the top