PCB Etching Workshop: Difference between revisions

Jump to navigation

Jump to search

Aaronn0130 (talk | contribs) started new page |

Aaronn0130 (talk | contribs) acid disposal |

||

| (6 intermediate revisions by 2 users not shown) | |||

| Line 1: | Line 1: | ||

===Preparing for the Workshop=== | ===Preparing for the Workshop=== | ||

# Make sure you've run through the workshop before the day of the workshop. There are many aspects to this workshop and it is important to be sure you have everything you need and everything is working properly. | |||

# This workshop is maximum of 8 people. If you only have 1 printer and/or 1 laminator consider reducing class to a size of 6. | |||

# This workshop can have pacing issues due to bottle necks in tool usage. This doesn't present a significant problem, but is something to keep in mind. Times while waiting to take turns with tools is a good opportunity for additional information to be communicated. | |||

==== Topics ==== | |||

# Overview of the process including alternatives | |||

# Copper clad variations and acid options (including disposal) | |||

# Transfer sheet and transfer method options | |||

# Hands on making! | |||

==== | === Steps === | ||

# Print design on paper and mock the board layout to make sure the print is scaled correctly and the mirroring is correct. | |||

# Cut transfer paper about an inch oversized and tape it to the original print. Print again on the glossy side of the paper. | |||

# Cut copper clad to approximate size - about an inch over sized again. | |||

# Using painters tape, tape 1 or 2 edges of the transfer to the copper. | |||

# Run through the laminator 5 - 10 times (until you're tired of doing it) | |||

# Soak copper and transfer in water for a couple of minutes, then peel off the transfer. | |||

# Use 2 sandwich bags and etch the board with ferric chloride | |||

# Drill the holes using drill press or dremel press. (Find the right bits and make sure it works with dremel and drill press) | |||

# Solder, Test, and Done! | |||

===Equipment & Supplies=== | |||

Maker sure you have the following: | |||

# A working laser printer with good toner for printing image onto transfer paper. | |||

# A computer for running the laser printer. | |||

# PCB design artwork ready to be printed (and has been tested). | |||

# Plenty of blue painters tape for securing paper to boards and paper to paper. | |||

# Sufficient amount of toner transfer paper for class. Have extra for mistakes. | |||

# Working laminator and clothes iron for applying heat during transfer process. | |||

# A way to cut copper to correct size (shear(s) or table saw can work, have it ready in advance). | |||

# Cleaning supplies to prepare copper; dish soap, sponge, paper towels, steel wool, fine-grit sandpaper (take your pick). | |||

# Containers for soaking boards after toner transfer is complete (small tupperwares work well for this). | |||

# Ferric chloride acid for etching boards. | |||

# Nitrile gloves for handling acid. | |||

# Sandwich bags for acid and copper (2 for each etch - double bag). | |||

# Container for acid desposal or funnell for putting acid back in original container (depending on depletion). | |||

# Correct size drill bits for hole drilling of PCB and fits available drill press. | |||

# Marker or other item for fixing broken traces. | |||

Here's a link to the equipment at hackrva for PCB etch: | Here's a link to the equipment at hackrva for PCB etch: | ||

[[PCB_Making_Equipment]] | [[PCB_Making_Equipment]] | ||

Here's a link to | Here's a link to an order supply list for this workshop: | ||

https://docs.google.com/spreadsheets/d/13CzrknA-gje8imDsIwGcc6N7ohlUdvaHhMr8B-QhfR0/edit#gid=0 | https://docs.google.com/spreadsheets/d/13CzrknA-gje8imDsIwGcc6N7ohlUdvaHhMr8B-QhfR0/edit#gid=0 | ||

Other Tips: | |||

# Make the traces and pads on the PCB artwork larger than needed to make etching easier. | |||

Disposal of Acid: | |||

People that etch a lot of board tend to save up acid then make a larger disposal. | |||

There are places that will dispose of acid - here is one: | |||

http://www.chesterfield.gov/content2.aspx?id=6442483267 | |||

===Example Projects for Teaching | ===Example Projects for Teaching=== | ||

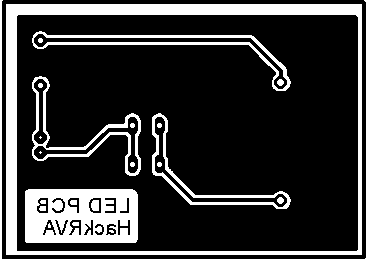

PCB Workshop Blinky 1 | PCB Workshop Blinky 1<br/> | ||

This is a simple LED board at about 2"x3" inches. | This is a simple LED board at about 2"x3" inches. | ||

[[File:Pcbworkshopblinky1.png]] | [[File:Pcbworkshopblinky1.png]] | ||

Parts List | ===Parts List=== | ||

(1) Button | * (1) Button | ||

(1) Battery Holder | * (1) Battery Holder | ||

(1) Resistor | * (1) Resistor | ||

(1) LED | * (1) LED | ||

Latest revision as of 15:04, 19 March 2016

Preparing for the Workshop

- Make sure you've run through the workshop before the day of the workshop. There are many aspects to this workshop and it is important to be sure you have everything you need and everything is working properly.

- This workshop is maximum of 8 people. If you only have 1 printer and/or 1 laminator consider reducing class to a size of 6.

- This workshop can have pacing issues due to bottle necks in tool usage. This doesn't present a significant problem, but is something to keep in mind. Times while waiting to take turns with tools is a good opportunity for additional information to be communicated.

Topics

- Overview of the process including alternatives

- Copper clad variations and acid options (including disposal)

- Transfer sheet and transfer method options

- Hands on making!

Steps

- Print design on paper and mock the board layout to make sure the print is scaled correctly and the mirroring is correct.

- Cut transfer paper about an inch oversized and tape it to the original print. Print again on the glossy side of the paper.

- Cut copper clad to approximate size - about an inch over sized again.

- Using painters tape, tape 1 or 2 edges of the transfer to the copper.

- Run through the laminator 5 - 10 times (until you're tired of doing it)

- Soak copper and transfer in water for a couple of minutes, then peel off the transfer.

- Use 2 sandwich bags and etch the board with ferric chloride

- Drill the holes using drill press or dremel press. (Find the right bits and make sure it works with dremel and drill press)

- Solder, Test, and Done!

Equipment & Supplies

Maker sure you have the following:

- A working laser printer with good toner for printing image onto transfer paper.

- A computer for running the laser printer.

- PCB design artwork ready to be printed (and has been tested).

- Plenty of blue painters tape for securing paper to boards and paper to paper.

- Sufficient amount of toner transfer paper for class. Have extra for mistakes.

- Working laminator and clothes iron for applying heat during transfer process.

- A way to cut copper to correct size (shear(s) or table saw can work, have it ready in advance).

- Cleaning supplies to prepare copper; dish soap, sponge, paper towels, steel wool, fine-grit sandpaper (take your pick).

- Containers for soaking boards after toner transfer is complete (small tupperwares work well for this).

- Ferric chloride acid for etching boards.

- Nitrile gloves for handling acid.

- Sandwich bags for acid and copper (2 for each etch - double bag).

- Container for acid desposal or funnell for putting acid back in original container (depending on depletion).

- Correct size drill bits for hole drilling of PCB and fits available drill press.

- Marker or other item for fixing broken traces.

Here's a link to the equipment at hackrva for PCB etch: PCB_Making_Equipment

Here's a link to an order supply list for this workshop: https://docs.google.com/spreadsheets/d/13CzrknA-gje8imDsIwGcc6N7ohlUdvaHhMr8B-QhfR0/edit#gid=0

Other Tips:

- Make the traces and pads on the PCB artwork larger than needed to make etching easier.

Disposal of Acid: People that etch a lot of board tend to save up acid then make a larger disposal. There are places that will dispose of acid - here is one: http://www.chesterfield.gov/content2.aspx?id=6442483267

Example Projects for Teaching

PCB Workshop Blinky 1

This is a simple LED board at about 2"x3" inches.

Parts List

- (1) Button

- (1) Battery Holder

- (1) Resistor

- (1) LED