Avid PRO6096: Difference between revisions

Updated approved and non-approved materials |

No edit summary |

||

| (7 intermediate revisions by the same user not shown) | |||

| Line 1: | Line 1: | ||

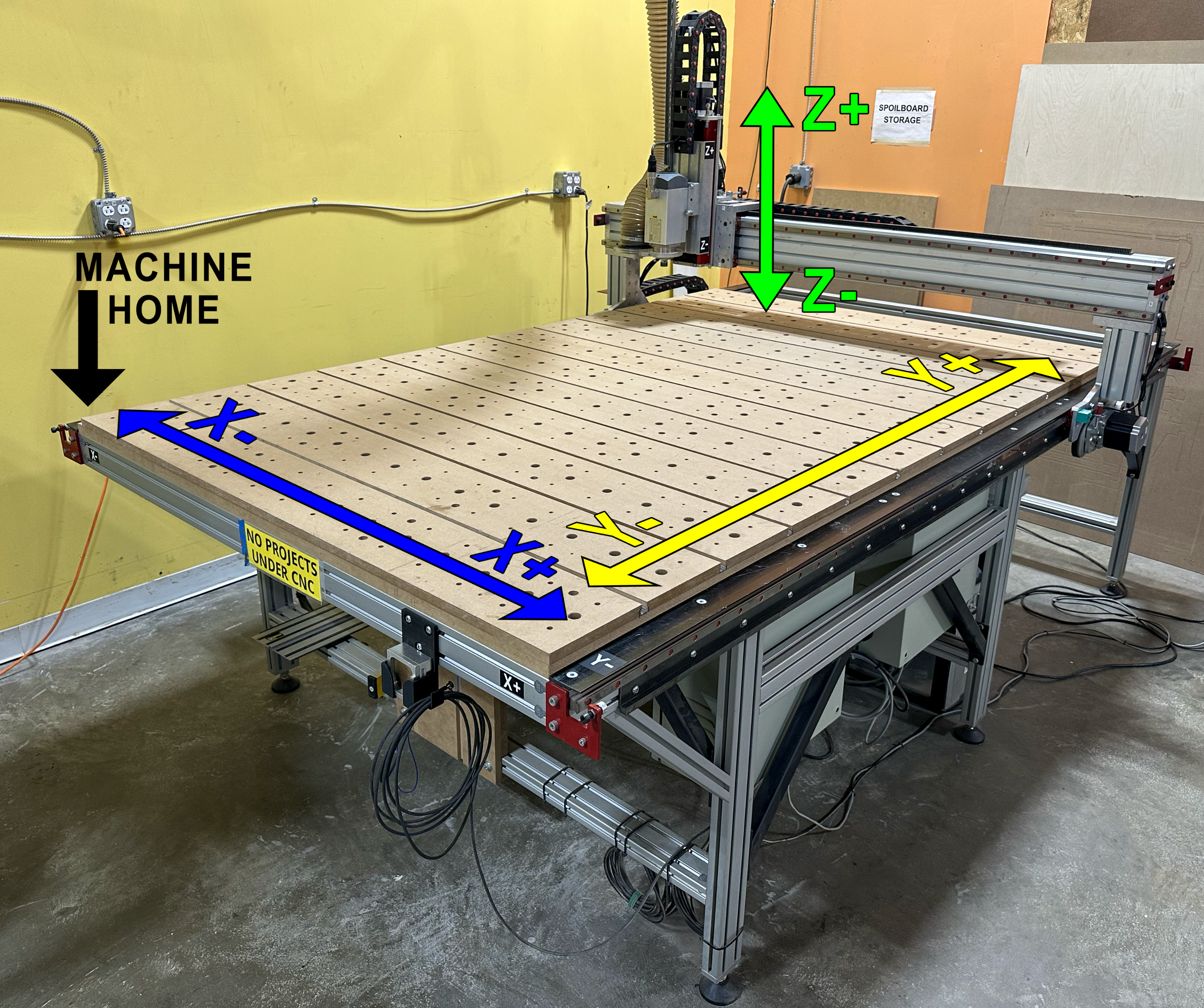

The Avid Pro Router is a 5' x 8' bed router that has a Plug-and-Play 2.2kW (3HP) Spindle. The CNC router was purchased in 2019 and completed assembly and installation in early 2020. | The Avid Pro Router is a 5' x 8' bed router that has a Plug-and-Play 2.2kW (3HP) Spindle. The CNC router was purchased in 2019 and completed assembly and installation in early 2020. | ||

[[File:Avid CNC. | [[File:HackRVA-Avid-CNC.png|none|thumb]] | ||

Specifications | == Specifications == | ||

* PRO6096 5’x8’ (Revision 19.2) purchased Jan 2020 | * PRO6096 5’x8’ (Revision 19.2) purchased Jan 2020 | ||

* Nema 34 CNC Controller Revision 20.1 - CRP800-00E-8, 2.2 kW Spindle (~3 HP) | * Nema 34 CNC Controller Revision 20.1 - CRP800-00E-8, 2.2 kW Spindle (~3 HP) | ||

* Avid Pro leg kit; standard gantry width/height | * Avid Pro leg kit; standard gantry width/height | ||

* VistaCNC P4-S Control Pendant | * VistaCNC P4-S Control Pendant | ||

* Mach4 Software | * Mach4 Software | ||

Current Modifications: (Updated 2/19/25) | |||

Current Modifications: (Updated 2/19/25) | * Frame is assembled according to Revision 24.2 Assembly Instructions allowing for vertical workholding. | ||

* Frame is assembled according to Revision 24.2 Assembly Instructions allowing for vertical workholding. | * Wiring on left side using “Alternate cable track location”. | ||

* Wiring on left side using “Alternate cable track location”. | |||

* Electronics boxes are mounted inside frame | * Electronics boxes are mounted inside frame | ||

Spoilboard | Spoilboard | ||

* MDF slats with locating pins | * MDF slats with locating pins | ||

* Aluminum T-track installed on the X-axis between MDF slats | |||

* 1/4-20 inserts in 4x4 grid | * 1/4-20 inserts in 4x4 grid | ||

* 3/4 dog holes in 4x8 grid | * 3/4" dog holes in 4x8 grid | ||

== CNC Workflow == | == CNC Workflow == | ||

This diagram describes the 4 high level steps to create a design and execute milling operations for that design on the Avid CNC. | This diagram describes the 4 high level steps to create a design and execute milling operations for that design on the Avid CNC. | ||

| Line 38: | Line 34: | ||

* Fiberglass | * Fiberglass | ||

* Carbon Fiber | * Carbon Fiber | ||

''*if you have a use case for a material not listed in the sections above, reach out in the CNC Slack channel for guidance before proceeding.'' | |||

== CNC Training Playlist == | == CNC Training Playlist == | ||

| Line 69: | Line 66: | ||

| colspan="2" |[https://www.youtube.com/watch?v=CnAlZiYjeiQ Mach4 User Guide: Auto Z and Corner Finding Touchplate] | | colspan="2" |[https://www.youtube.com/watch?v=CnAlZiYjeiQ Mach4 User Guide: Auto Z and Corner Finding Touchplate] | ||

|A quick video giving a more detailed overview of the touch plate used to establish initial X, Y and Z offsets for your program. | |A quick video giving a more detailed overview of the touch plate used to establish initial X, Y and Z offsets for your program. | ||

|- | |||

| colspan="2" |[https://www.youtube.com/watch?v=TFaLVQYKo3c CNC Router Feeds and Speeds Explained] | |||

|A brief video from IDC Woodcraft that explains the concepts of setting appropriate feed (how fast the spindle moves laterally) and speed (the RPM of the bit in the spindle) values. | |||

Basic chipload calculator: https://idcwoodcraft.com/pages/chipload-calculator | |||

|- | |- | ||

| colspan="2" |[https://www.youtube.com/watch?v=htEH2ablRWU Spindle Warmup Overview] | | colspan="2" |[https://www.youtube.com/watch?v=htEH2ablRWU Spindle Warmup Overview] | ||

|A short video describing the spindle warmup procedure and why it is an important part of the initial startup procedure for the Avid CNC. | |A short video describing the spindle warmup procedure and why it is an important part of the initial startup procedure for the Avid CNC. | ||

|- | |||

| colspan="2" |[https://www.youtube.com/watch?v=a1xUOK7UY3Y How to run an air pass on the Avid CNC] | |||

|This short video demonstrates how to run an air pass above your material on the CNC. | |||

|} | |||

== CNC Tool Libraries == | |||

{| class="wikitable" | |||

|+ | |||

!Tool Libraries | |||

|- | |||

|[https://spetools.com/pages/spetool-tool-file-database SpeTool] | |||

|- | |||

|Whiteside [https://www.whitesiderouterbits.com/pages/vectric-tool-files (Vectric)] [https://www.whitesiderouterbits.com/pages/fusion-360-tool-files (Fusion360)] | |||

|- | |||

|[https://idcwoodcraft.com/pages/database-downloads IDC Woodcraft] | |||

|- | |||

|[https://www.freudtools.com/products/70-103 Freud (VCarve only - requires login)] | |||

|} | |} | ||

Latest revision as of 06:16, 13 October 2025

The Avid Pro Router is a 5' x 8' bed router that has a Plug-and-Play 2.2kW (3HP) Spindle. The CNC router was purchased in 2019 and completed assembly and installation in early 2020.

Specifications

- PRO6096 5’x8’ (Revision 19.2) purchased Jan 2020

- Nema 34 CNC Controller Revision 20.1 - CRP800-00E-8, 2.2 kW Spindle (~3 HP)

- Avid Pro leg kit; standard gantry width/height

- VistaCNC P4-S Control Pendant

- Mach4 Software

Current Modifications: (Updated 2/19/25)

- Frame is assembled according to Revision 24.2 Assembly Instructions allowing for vertical workholding.

- Wiring on left side using “Alternate cable track location”.

- Electronics boxes are mounted inside frame

Spoilboard

- MDF slats with locating pins

- Aluminum T-track installed on the X-axis between MDF slats

- 1/4-20 inserts in 4x4 grid

- 3/4" dog holes in 4x8 grid

CNC Workflow

This diagram describes the 4 high level steps to create a design and execute milling operations for that design on the Avid CNC.

Approved Materials

The following materials are approved for use on the AVID CNC. In many cases, notably with plastics, bit selection is crucial to execute cuts correctly. Be sure you have researched your use case thoroughly.

- Wood (hardwood, softwood, various plywoods, MDF)

- Plastics (PVC, Acrylic, HDPE, Polycarbonate)

- Foam (polystyrene and polyurethane)

Non-Approved Materials

The following materials are not approved for use on the AVID CNC at HackRVA for safety and operational reasons.

- No metals of any kind

- Fiberglass

- Carbon Fiber

*if you have a use case for a material not listed in the sections above, reach out in the CNC Slack channel for guidance before proceeding.

CNC Training Playlist

- This is a short list of videos that all interested members should watch to become familiar with the design tools, startup process, and operation procedures for the Avid CNC.

- Watching these videos is not a substitute for formal training—members must still be certified before using the CNC independently.

- For the design videos, it is not necessary to watch both VCarve and Fusion 360 (but not a bad idea). Select the video for the design software you intend to use. If you are not already familiar with either tool, we recommend VCarve.

- After you have watched these videos to get a grounding in the fundamentals of the design and operation process, reach out in the CNC channel in Slack to meet up with a trainer who can walk you through the next steps.

| Design | ||

|---|---|---|

| Vectric

VCarve |

VCarve Training Video Series | A series of videos that walk through the creation of simple beginner projects in VCarve |

| VCarve and Mach 4 Walkthrough | This video will walk though the creation of a simple tray with various recesses, using VCarve to design the part and create the toolpaths that the CNC will execute. | |

| Fusion360 | Fusion 360 and Mach 4 Walkthrough | This video will walk though the creation of a simple tray with various recesses, using Fusion360 to design the part and create the toolpaths that the CNC will execute. |

| Execute | ||

| Avid CNC - Start Up Procedure and Cycle Start Checklist | This video covers the steps that are taken to initially startup the Avid CNC, and the steps that are taken each time a program (exported G-Code) is executed. | |

| Mach4 User Guide: Auto Z and Corner Finding Touchplate | A quick video giving a more detailed overview of the touch plate used to establish initial X, Y and Z offsets for your program. | |

| CNC Router Feeds and Speeds Explained | A brief video from IDC Woodcraft that explains the concepts of setting appropriate feed (how fast the spindle moves laterally) and speed (the RPM of the bit in the spindle) values.

Basic chipload calculator: https://idcwoodcraft.com/pages/chipload-calculator | |

| Spindle Warmup Overview | A short video describing the spindle warmup procedure and why it is an important part of the initial startup procedure for the Avid CNC. | |

| How to run an air pass on the Avid CNC | This short video demonstrates how to run an air pass above your material on the CNC. | |

CNC Tool Libraries

| Tool Libraries |

|---|

| SpeTool |

| Whiteside (Vectric) (Fusion360) |

| IDC Woodcraft |

| Freud (VCarve only - requires login) |